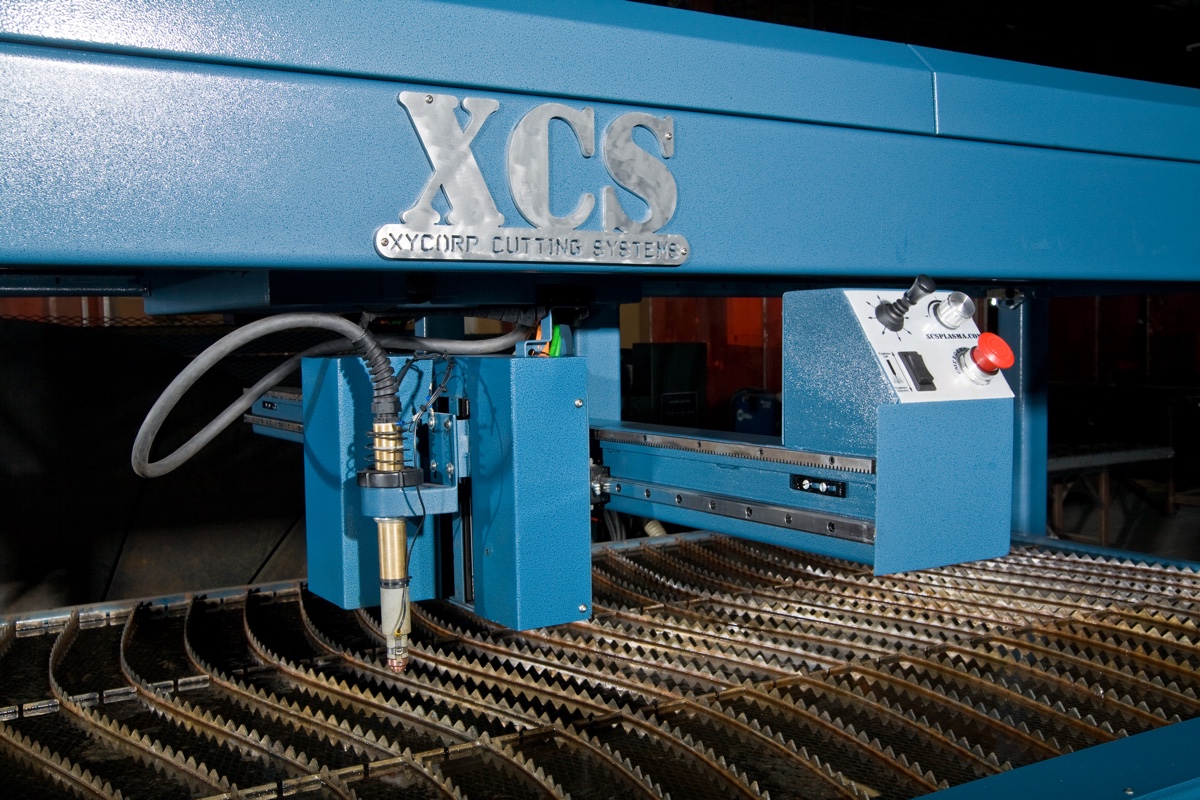

XCS-2000 CNC Plasma Cutter

Whether you are a job shop, HVAC shop, ornamental iron shop, or manufacturer, you’ll appreciate the rugged and robust construction of the XCS-2000 Series of computerized plasma cutting machines. Built to handle up to 1 3/4″ steel plate, this machine will give you years of trouble-free production. Like all XCS models, a full featured automatic torch height control and is standard, as well as simple-to-operate SimplePath® CNC Control Software.

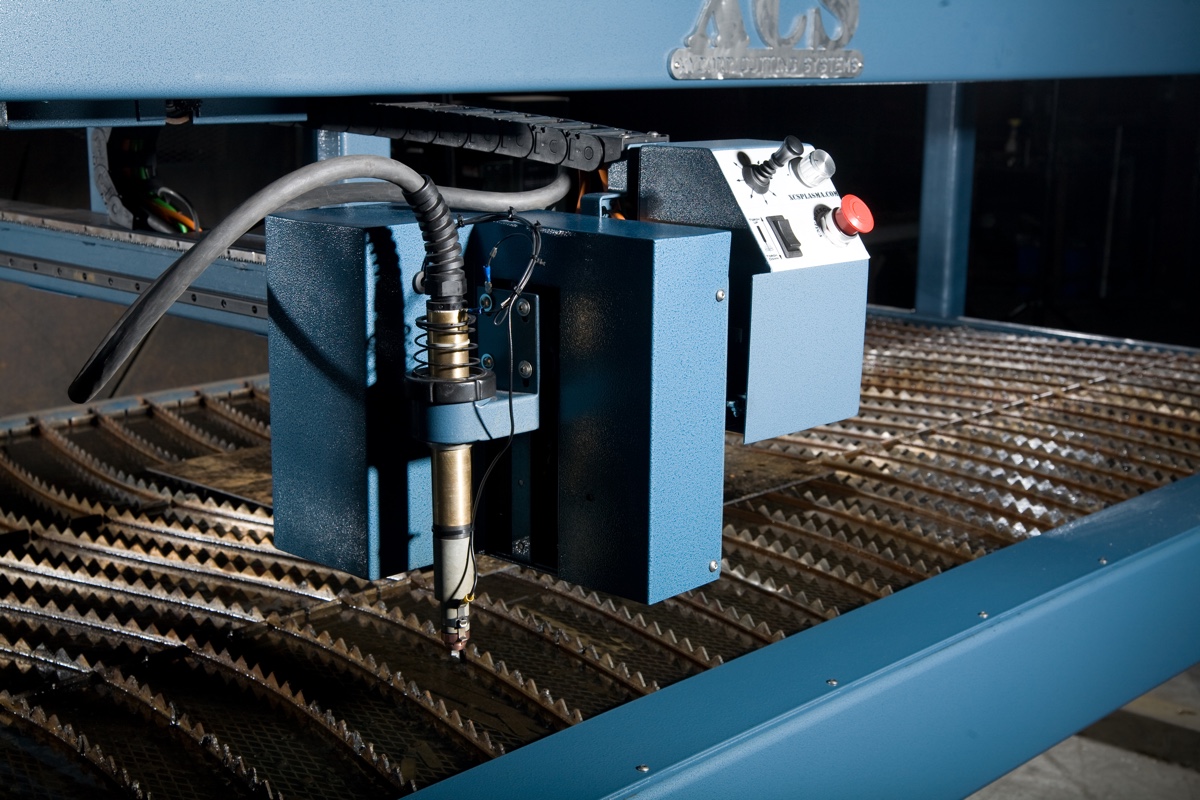

The XCS-2000 Series design featuring X and Y axes drives mounted on the overhead gantry means years of problem-free operation since there is almost no possibility of slag, splatter, or water entering and damaging the drives. The XCS-2000 Series integrated (but replaceable) water table, capable of handling large plates, eliminates the need for exhaust removal and filtration since there is almost no smoke. Since the parts can be handled immediately after cutting, higher production rates can be achieved. The XCS-2000 Series Z-axis travel is 6″ so you can cut up to 4″ square tubing.

| CUTTING AREA | 5′ x 10′ or Custom Table Size |

| CUTTING CAPACITY | (Mild Steel) |

| Pierce | 1/2″ (12mm) |

| Edge Start | 1 3/4″ (44mm) |

| CONTROLLER | PC-based XCS SimplePath software |

| DRIVE SYSTEM | |

| X and Y axes: | Servo motors to rack and pinion |

| Torch height: | Servo motor to ballscrew (6″ of travel) |

| TRAVERSE SPEED | 900 inches per minute (max) |

| POSITIONING ACCURACY | +/- .005″ |

| REPEATABILITY | +/- .001″ |

| STANDARD PLASMA UNIT | Hypertherm Powermax |

| Plasma Gas: | Air |

| Shield Gas: | Air |

| SOFTWARE | Xycorp SimplePath |

| Features: | PC-based, Windows XP |

| Ohmic sensing | |

| Automatic cutting path control | |

| Auto torch height control | |

| Nesting | |

| TABLE TYPE | Water Table |

| OPTIONS | Larger or smaller plasma units |

| Automatic parts nesting software | |

| Down-draft table with filtration | |

| Custom sized cutting tables | |

| Custom designed machines |

How Can We Help?

Contact us with questions, inquiries on technical specs, or requests for custom machinery development. We’re here to help!

Contact Us Form

We are running our machine two shifts, every day of the week